In RF circuit design, performance issues rarely announce themselves clearly. A filter fails to meet its target bandwidth, an impedance match drifts across temperature, or a prototype behaves differently from simulation. In many cases, these problems are not caused by flawed topologies, but by components that behave differently in practice than they do on paper.

For engineers under pressure to shorten development cycles, predictability becomes just as important as raw performance. And this is where inductor selection quietly plays a decisive role.

When Simulation and Reality Don’t Match

Modern RF designs rely heavily on simulation tools to validate performance before hardware is built. Yet even with accurate models, real-world results often deviate—sometimes subtly, sometimes significantly.

One common reason is the behavior of magnetic core materials at high frequencies. Ferrite-core inductors may meet nominal inductance values at low frequencies, but their characteristics shift as frequency, temperature, and signal amplitude change. These shifts introduce uncertainty that is difficult to model precisely.

For engineers, this means additional tuning, multiple board spins, and extended debugging cycles.

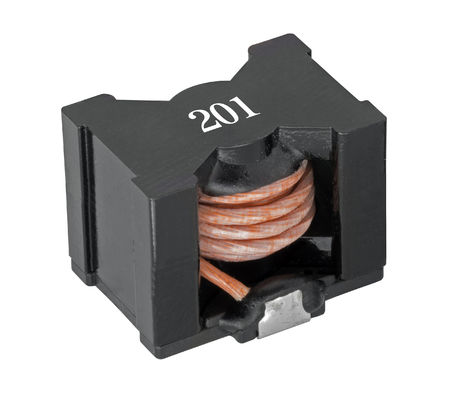

Air Core Inductors and Design Transparency

Air core RF inductors behave differently because they remove one of the largest unknowns: the magnetic core itself. Without core saturation, hysteresis, or permeability variation, the inductance remains fundamentally tied to geometry rather than material behavior.

This makes air core inductors inherently more transparent in design. What engineers calculate and simulate is far closer to what they measure on the bench. In high-frequency circuits, this consistency can significantly reduce the gap between theoretical performance and real-world results.

Predictability, in this context, is not just convenient—it directly affects development efficiency.

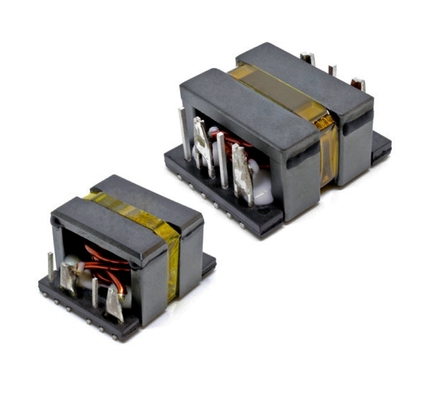

Why SMD Packaging Changes the Equation

Historically, air core inductors were associated with through-hole designs or manually tuned components. While effective, they were not always compatible with automated assembly or compact layouts.

SMD air core RF inductors change this dynamic. By combining air core performance with surface-mount compatibility, they allow engineers to integrate predictable inductance into modern manufacturing workflows without sacrificing repeatability.

This is especially valuable in designs that must scale from prototype to volume production without introducing new variables.

Reducing Debug Time in RF Applications

In RF front ends, impedance matching networks, oscillators, and broadband filters are often the most sensitive parts of the circuit. Small inductance variations can shift operating points or introduce unwanted resonances.

By using components with stable, linear behavior across frequency, engineers can focus their debugging efforts on system-level optimization rather than compensating for component variability. Over time, this approach reduces design iterations and increases confidence in performance margins.

In many cases, the value of air core inductors lies not in headline specifications, but in the problems they prevent from occurring.

Balancing Size, Performance, and Risk

Of course, no component choice is without trade-offs. Air core inductors generally require more board area to achieve a given inductance value compared to ferrite-core alternatives. In highly space-constrained designs, this can be a limiting factor.

However, in RF systems where reliability and repeatability are priorities, engineers often accept this trade-off to minimize downstream risk. The cost of additional board space is frequently lower than the cost of late-stage redesigns or performance shortfalls in the field.

Seen from this perspective, inductor selection becomes a form of risk management rather than simple optimization.

A System-Level View of Passive Components

As RF systems become more complex and integrated, passive components are no longer passive decisions. Their behavior influences tuning stability, production yield, and long-term reliability.

Engineers who treat inductors as system-level elements—rather than interchangeable parts—are better positioned to deliver consistent results. Air core designs support this mindset by offering behavior that is easier to anticipate and control.

How This Design Philosophy Aligns with Our SMD Air Core RF Inductors

At SHINHOM, our SMD air core RF inductors are developed to support engineers who value consistency as much as performance. By focusing on stable inductance, high Q factor, and repeatable manufacturing, these components help reduce uncertainty in RF designs.

They are particularly suited for applications where predictable behavior simplifies tuning, shortens development cycles, and improves confidence from prototype to production.

If you are evaluating ways to improve design transparency and reduce RF debugging time, our team is available to discuss application considerations at sales@shinhom.com.

Designing for Confidence, Not Just Compliance

Meeting specifications is only part of successful RF design. Confidence—in simulation results, component behavior, and production outcomes—is what allows teams to move faster without compromising quality.

Sometimes, that confidence starts with choosing components that behave exactly as expected.

Your message must be between 20-3,000 characters!

Please check your E-mail!

Your message must be between 20-3,000 characters!

Please check your E-mail!